Dec, 31 2025

Dec, 31 2025

What Is Noise-Induced Hearing Loss?

Noise-induced hearing loss (NIHL) isn’t something that sneaks up on you slowly over decades. It starts with a quiet, unnoticed shift in how you hear - a coworker’s voice sounding muffled, the TV turning up louder, or struggling to follow conversations in a busy break room. By the time you notice, the damage is already done. NIHL is caused by exposure to loud sounds at work, and once the hair cells in your inner ear are destroyed, they never grow back. This isn’t temporary ringing in the ears - it’s permanent hearing loss, and it’s completely preventable.

The problem is widespread. According to the CDC, 22 million U.S. workers are exposed to dangerous noise levels every year. The Bureau of Labor Statistics found that in 2022, nearly 20,000 cases of hearing loss required workers to take time off. These aren’t just numbers - they’re people. A welder who can’t hear his supervisor’s warning. A factory operator who misses a machine alarm. A miner who can’t hear his teammate calling for help.

The key thing to understand: NIHL is not caused by occasional loud noises. It’s caused by repeated exposure to sounds at or above 85 decibels (dBA) over time. That’s the noise level of heavy traffic, a lawnmower, or a power tool running for hours. The longer you’re exposed, the worse it gets. And unlike a broken bone or a cut, your body can’t heal this damage.

Why 85 dBA Is the Line - And Why It’s Not Safe

Most workplaces follow the rule that 85 dBA is the threshold where hearing protection becomes required. But here’s the truth: 85 dBA isn’t a safe level. It’s the point where hearing loss begins. The National Institute for Occupational Safety and Health (NIOSH) says that even at 85 dBA, you’re at risk after just eight hours of exposure. And if the noise goes up by just 3 more decibels - to 88 dBA - your safe exposure time drops to four hours. At 91 dBA, it’s only two hours. At 94 dBA? One hour.

Here’s why that matters: the Occupational Safety and Health Administration (OSHA) still allows up to 90 dBA for eight hours. That’s 16 times more noise energy than NIOSH recommends. Think of it like this: OSHA says it’s okay to drink one glass of alcohol an hour. NIOSH says that’s already too much. The difference isn’t just paperwork - it’s your hearing.

And it’s not just the volume. The frequency matters too. NIHL typically starts in the 3,000 to 6,000 Hz range - the frequencies you need to understand speech clearly. That’s why people with NIHL often say, “I can hear you, but I can’t understand what you’re saying.” They’re losing the ability to hear consonants like s, t, k, and p. This isn’t just annoying - it’s dangerous on the job.

Engineering Controls: The Best Way to Protect Hearing

The most effective way to prevent hearing loss isn’t by giving workers earplugs. It’s by removing the noise at the source. That’s called engineering control - and it’s the top of the safety hierarchy for a reason.

Examples? Replace old, loud air compressors with quieter models. Install sound-dampening enclosures around noisy machinery. Use vibration isolators under presses or saws. Add acoustic panels to walls and ceilings in factories. In one NIOSH case study, a mining operation reduced noise from 98 dBA to 82 dBA by installing barriers around drilling equipment. Workers didn’t just hear better - they reported less fatigue and better focus.

These fixes aren’t expensive in the long run. A 2021 NIOSH analysis found that for every dollar spent on hearing conservation programs, companies saved $5.50 in workers’ compensation claims. And with the global hearing protection market hitting $1.27 billion in 2022, companies are starting to realize that buying quieter equipment is smarter than buying more earplugs.

California’s 2023 regulations now require employers to try engineering controls before relying on hearing protection. That’s the right direction. If you can reduce noise at the source, you don’t have to depend on workers to remember to wear their protection - or hope they insert earplugs correctly.

Why Earplugs Often Fail - And How to Make Them Work

Let’s be honest: most workers don’t wear hearing protection the way they’re supposed to. A NIOSH survey found only 38% of workers in high-noise jobs wear their earplugs consistently. Why? Because they’re uncomfortable. Because they can’t hear coworkers or alarms. Because the cheap foam ones fall out after two hours.

Even when workers do wear them, they often use them wrong. A 2017 Cochrane review found that 75% of people insert foam earplugs incorrectly. That means instead of getting 30 dB of protection, they’re only getting 15-20 dB - barely enough to make a difference. Real-world performance is always lower than lab ratings.

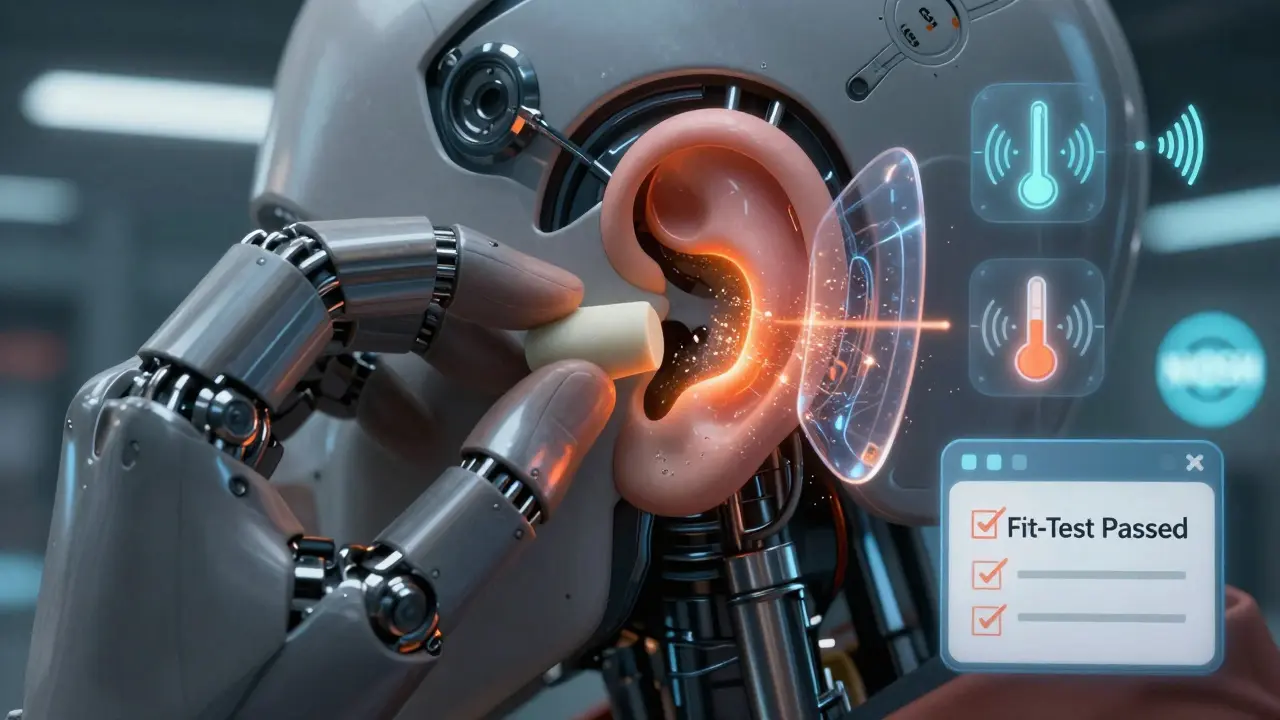

The solution? Fit-testing. Real Ear Attenuation at Threshold (REAT) measurements check exactly how much noise reduction each worker is actually getting. Custom-molded earplugs, made from impressions of the ear, provide consistent 25-30 dB of protection and are far more comfortable over long shifts. Some new models, like 3M’s PELTOR TS3+, even have built-in microphones that let workers hear speech and alarms while still blocking harmful noise.

Training matters too. A 10-15 minute one-on-one session on how to insert earplugs correctly can double the effectiveness. And if workers are involved in choosing the protection they use, compliance jumps from 50% to 87%.

What a Real Hearing Conservation Program Looks Like

A good hearing conservation program isn’t just handing out earplugs and calling it a day. It’s a system. NIOSH’s 2023 guidelines outline five key steps:

- Noise monitoring - Use calibrated sound level meters to measure noise levels in every job area. Don’t guess. Measure.

- Engineering controls - Fix the noise at the source before relying on personal gear.

- Proper hearing protection - Offer multiple types (foam, silicone, custom), and let workers choose. Fit-test them.

- Annual audiograms - Test hearing every year at 500, 1000, 2000, 3000, 4000, and 6000 Hz. A shift of 10 dB or more at 2000-4000 Hz means trouble.

- Worker training - Teach people why this matters. Show them real stories. Let them ask questions.

Companies that do this right see results. In one manufacturing plant, after adding fit-testing and custom earplugs, the number of workers with hearing loss dropped by 40% in three years. The key? Management didn’t just approve the program - they were in the shop every week asking workers, “Are your earplugs working?”

The Hidden Costs - And Why This Isn’t Just About Hearing

NIHL isn’t just about losing your ability to hear your grandkids. It’s about safety, productivity, and mental health.

Workers with hearing loss are more likely to miss verbal warnings, mishear instructions, or misunderstand safety procedures. Studies show they’re at higher risk of accidents. They also report more stress and social isolation. Tinnitus - that constant ringing in the ears - affects up to 70% of workers with NIHL. It’s not just noise. It’s sleepless nights, anxiety, and depression.

And the financial cost? The average workers’ compensation claim for hearing loss is $14,700. Multiply that by thousands of cases, and you’re talking about hundreds of millions of dollars a year. Meanwhile, the global market for hearing protection is growing at 5.2% annually - proof that companies are finally realizing they’re spending more on lawsuits than on prevention.

What’s Changing - And What You Need to Know

The rules are starting to catch up to the science. In 2023, NIOSH launched its “Buy-Quiet” initiative, a free database of over 1,200 low-noise tools and machines. You can search by type - saws, drills, compressors - and find models that are 3 to 15 dBA quieter than the standard version.

OSHA’s 2023 National Emphasis Program is now targeting construction, manufacturing, and agriculture - the three industries with the highest rates of NIHL. They’re doing 5,000+ inspections a year, and fines are rising.

Even more important: researchers are finding early signs of hearing damage before it shows up on audiograms. Scientists at the University of Southern California are testing biomarkers in blood that can detect inner ear stress before permanent damage occurs. This could mean catching problems before they become irreversible.

The bottom line? The old way of thinking - that 85 dBA is “safe” - is outdated. NIOSH is pushing for a new limit of 80 dBA by 2025. The European Union already uses 80 dBA as an action level. If you’re still using 90 dBA as your benchmark, you’re playing Russian roulette with your workers’ hearing.

What You Can Do Right Now

If you’re an employer: Measure your noise levels. Fix the loudest machines first. Offer better hearing protection - not just foam plugs. Train your team. Involve them in choosing solutions. Track your results.

If you’re a worker: Don’t wait until you can’t hear your kids. If your earplugs hurt, complain. Ask for custom ones. If you can’t hear alarms or coworkers, speak up. Your hearing is not replaceable.

If you’re a safety manager: Don’t just check the box on OSHA paperwork. Build a culture where hearing protection is normal, comfortable, and respected. Make it part of your daily conversations - not just an annual training.

NIHL is permanent. But it’s also avoidable. Every quiet machine, every properly fitted earplug, every worker who speaks up - that’s how you stop it.

Can noise-induced hearing loss be reversed?

No. Once the hair cells in your inner ear are damaged by loud noise, they don’t regenerate. The hearing loss is permanent. That’s why prevention is the only effective strategy - there’s no cure.

What noise levels are dangerous at work?

Any noise at or above 85 dBA for eight hours a day is considered hazardous. For every 3 dB increase, safe exposure time is cut in half. So 88 dBA is safe for only four hours, 91 dBA for two hours, and 94 dBA for just one hour. OSHA allows up to 90 dBA, but NIOSH says even 85 dBA is too high.

Are earplugs enough to protect hearing?

Not by themselves. Earplugs are the last line of defense. The most effective protection comes from reducing noise at the source - through engineering controls like enclosures, quieter equipment, or barriers. Even the best earplugs only work if they’re worn correctly and consistently - and most workers don’t.

How often should workers get hearing tests?

Workers exposed to noise at or above 85 dBA should get a baseline hearing test within six months of starting the job, then annual tests. Testing should cover 500, 1000, 2000, 3000, 4000, and 6000 Hz frequencies. A shift of 10 dB or more at 2000-4000 Hz is considered a standard threshold shift and signals early hearing loss.

What industries have the highest risk of noise-induced hearing loss?

Construction (22% of workers exposed), manufacturing (19%), mining (17%), and agriculture (15%) have the highest rates of noise exposure. These industries often use loud tools like jackhammers, saws, compressors, and machinery that run constantly. OSHA’s 2023 National Emphasis Program specifically targets these sectors for inspections.

Is there a new technology that helps prevent hearing loss?

Yes. Smart hearing protection devices like 3M’s PELTOR TS3+ monitor noise exposure in real time and record data for compliance. They also allow communication - workers can hear speech and alarms while still blocking harmful noise. Research is also underway to detect early signs of hearing damage through blood biomarkers, before it shows up on audiograms.

What’s the best way to get workers to wear hearing protection?

Don’t just hand out earplugs. Let workers choose the type that works for them - custom-molded, silicone, or electronic. Train them personally on how to insert them correctly. Fit-test their protection to make sure it’s working. And most importantly, involve them in choosing noise-reducing solutions. When workers help design the system, compliance jumps from under 40% to over 85%.

Stewart Smith

December 31, 2025 AT 19:35Aaron Bales

January 1, 2026 AT 18:24Paul Huppert

January 2, 2026 AT 13:59Sara Stinnett

January 2, 2026 AT 19:29Darren Pearson

January 4, 2026 AT 11:41John Chapman

January 5, 2026 AT 13:24Joy Nickles

January 6, 2026 AT 10:21Lawver Stanton

January 8, 2026 AT 03:39Brady K.

January 9, 2026 AT 21:19Jenny Salmingo

January 10, 2026 AT 16:42Frank SSS

January 11, 2026 AT 18:30Aaron Bales

January 12, 2026 AT 16:26Kayla Kliphardt

January 14, 2026 AT 13:37Martin Viau

January 15, 2026 AT 21:48